From Concept to Delivery

- Immediate response and flexibility to meet customer's requirements, with emphasis on reliability and high quality.

- Comprehensive and professional engineering solutions from customers preliminary design, through development of first articles (prototypes), up to serial production... from design to finish!

- Comprehensive engineering consulting including professional seminars held for our clients.

- Casting Simulation where needed.

- Castings produced from a variety of alloys: A356, A357, C355, A201, A203, A204, A206, and Unifont-90.

- Orders accepted from a single unit up to any required quantity.

- Casting weights vary from few grams up to hundreds of Kgs.

- Fast development of prototypes and ability of producing large volumes of serial production.

- Finishing, straightening and sandblasting.

- Well-equipped, in-house machining department.

- Capability of supplying coated and painted castings.

Patterns:

CNC modeling retrieved directly from the customers' 3-D CAD files. R.P. modeling in various methods is available. This unique department combines CAD and CAM processes, and conventional methods, which enables fast reaction in tight-schedule projects.

3D Printing

3D Sand printing of cores and molds.

High speed deliveryof prototypes: only 5 working days for getting finished part.

Complexity: No need to watch out for undercuts.

Cost-effective: Quick and efficient production of models without elaborate and expensive mold equipment.

Combination: 3D printed complex cores can be combined with the traditional in-house sand mold.

Easy de-coring after casting: Due to low binder content of cores and hence easier outgassing of components.

Optimization of tools: Optimize your tool using tests with 3D printed moldes befor finelize tooling.

Complex-core molds:

Our highly trained staff can deal with complicated molds that vary from 1 Kg to 4 Tons, up to 2x2x2 meter.

Heat treatments:

homogenization, aging and stress relief treatments in new and certified furnaces.

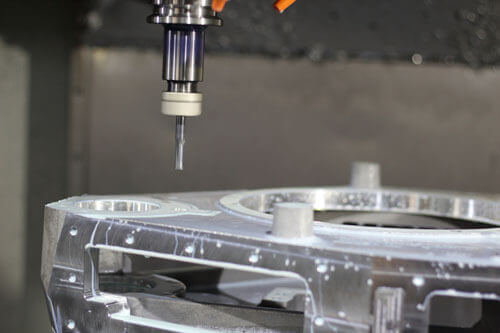

Machining

12 machining centers up to1600x820x1030 mm, 4 axis and 5 axis. Operated by professional team, experties in complementary machining of castings.